Analysis of Productivity Measurement in CPO Production Using OMAX Method

DOI:

https://doi.org/10.12928/si.v21i2.145Keywords:

Analytical Hierarchy Process, CPO, FMEA, OMAXAbstract

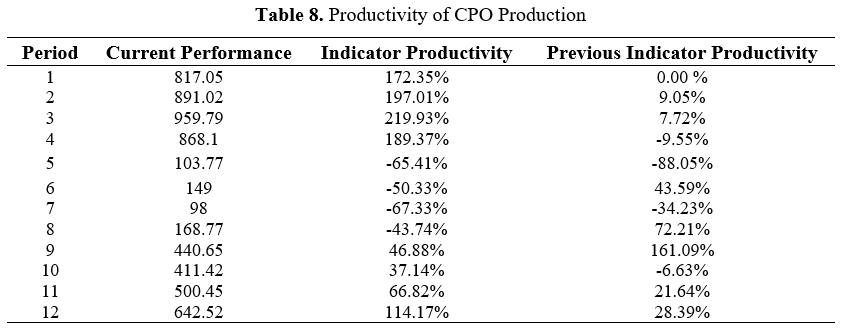

The primary focus of this research revolves around the measurement of productivity and the factors that impact Crude Palm Oil (CPO) production which currently faces challenges in assessing whether existing productivity falls into the 'satisfactory' category. The contribution of this study is conducting a comprehensive productivity assessment, focusing on metrics and identifying the causes of productivity decline, especially potential points of failure. The measurement indicators use the Objective Matrix (OMAX) method which includes five ratios, including raw material utilization, energy consumption, labor efficiency, optimization of production targets, and production capacity utilization. The Analytical Hierarchy Process (AHP) is used to assign relative weight to factors that contribute to overall productivity. In addition, Failure Modes and Effects Analysis (FMEA) functions as a tool to determine the causes of decreased productivity by considering the potential for failure to occur. The research results show that productivity reached its highest point in March at 219.93% and the lowest in July at -67.33%. Based on the score assessment, this decline was mainly caused by the lack of optimal achievement of production targets, symbolized by a ratio of 4 to a score of 45. Potential causes for this ratio include non-compliance in selecting FFB that meets standards, and production standards that are too ambitious. targets, and mental and physical fatigue and stress. To improve overall performance, proposed improvements include the application of Internet of Things (IoT) technology, such as the use of sensors and automation systems in production processes, as well as investment in agricultural technology as a monitoring system. This increase is aimed at achieving higher production targets and overall efficiency.

References

Aji, P., & Nugroho, A. J. (2022). Productivity Measurement Analysis of Ready Mix Concrete with the OMAX (Objective Matrix) Method at PT Pionirbeton Industri. Scientific Journal of Mechanical, Electrical and Computer Engineering, 2(3). https://doi.org/10.51903/juritek.v2i3.447

Asihydiq, H., Dahniar, T., & Zulziar, M. (2021). Analysis Productivity of Bass String Production Process Using the OMAX Method to Increase Production Targets at PT. Yamaha Indonesia. Scientific Journal of Industrial Engineering and Management, 4(2). https://doi.org/10.32493/jitmi.v4i2.y2021.p91-97

Basori, F. I. Muflihah, N. Ghani, S. R. W. & Afiatna, F. A. N. F. (2022). Productivity Analysis with the Objective Matrix (OMAX) Method in Home Industry X. Journal of Industrial Innovation and Management, 1(2). https://doi.org/10.33752/invantri.v1i2.2320

Celina, J. S., Kusumawardani, D. M., & Fathoni, M. Y. (2022). Evaluation of Library Supply Chain Performance at the Telkom Institute of Technology Purwokerto Using the Supply Chain Operational Reference (SCOR) Model Based on Objective Matrix (OMAX). Computer Research Journal, 9(2), 296–304. https://doi.org/10.30865/jurikom.v9i2.4014

Fradinata, E., Marsella, B., & Izzaty, N. (2022). Productivity Measurement Using the Objective Matrix Method in the UD Production Process. Teungku Aceh coffee. Journal of Serambi Engineering, VII(3), 3353–3364. https://doi.org/10.32672/jse.v7i3.4494

Handayani, W., & Susilowati, N. (2021). Analysis of Productivity Measurement in the Foundry Section of PT. Apie Indo Karunia with the Objective Matrix Method. Management And Business, 6(1). 1–13. https://doi.org/10.33005/mebis.v6i1.201

Hardiantara, Y., Kusmindari, C. D., & Zahri, A. (2019). Analysis of Productivity Gas Power Plants using the Objective Matrix (OMAX) Method (Case Study: PT SA ARY INDORAYA). Journal of Techno, 16(April), 17–37. https://doi.org/10.33557/jtekno.v16i1.357

Hidayatullah, S., Dahda, S. S., & Ismiyah, E. (2021). Company Performance Measurement Using the Objective Matrix (OMAX) and Analytical Hierarchy Process (AHP) Methods. Journal of Systems and Industrial Engineering, 2(2), 270–277. http://dx.doi.org/10.30587/justicb.v2i2.3668

Ilhami, R. I., Dahda, S. S., & Ismiyah, E. (2022). Productivity Measurement Analysis Using the Objective Matrix (OMAX) Method at UD Risslin Gresik. Journal of Systems And Industrial Engineering, 3(1), 32–42. http://dx.doi.org/10.30587/justicb.v3i1.4755

Komariah, I. (2019). Measuring Production Floor Productivity Using the Objective Matrix (OMAX) Method at PT. XYZ. Galuh Industrial Journal, 1(1), 16–20. https://doi.org/10.25157/jig.v1i1.2984

Mawarni, C., & Azizah, F. N. (2023). Application of the AHP Supplier Selection Method in Procurement of Raw Materials at PT XYZ. Research and Technology Innovation Writing Unit, 7(3). http://dx.doi.org/10.30998/string.v7i3.14584

Mukti, A. R., A’yun, Q., & Suparto. (2021). Productivity Analysis Using the Objective Matrix (OMAX) Method (Case Study: Production Department of PT Elang Jagad). Journal Of Management And Technology 13–18. https://doi.org/10.31284/j.jtm.2021.v2i1.1525

Prasetyo, W., Hermaliani, E. H., & Hasanah, R. L. (2023). Decision Support System for Selection of the Best Employees Using the AHP Method at PT Telkom Witel Kalbar. Computer Science (CO-SCIENCE), 3(1), 8–16. https://doi.org/10.31294/coscience.v3i1.1351

Puteri, R. A. M. (2017). Measurement of productivity parcial at PT. Aneka Cipta Sealindo. Jurnal Teknologi, 9(1). https://doi.org/10.24853/jurtek.9.1.13-20

Ramayanti, G., Sastraguntara, G., & Supriyadi. (2020). Productivity Analysis Using the Objective Matrix (OMAX) Method on the Production Floor of Beverage Bottle Companies. INTECH Journal of Industrial Engineering, 6(1), 31–38. http://dx.doi.org/10.30656/intech.v6i1.2275

Setiowati, R. (2017). Analysis of Productivity Measurement of the Production Department with the Objective Matrix (Omax) Method on CV. Jaya Mandiri. Exacta factor 10(3), 199–209. http://dx.doi.org/10.30998/faktorexacta.v10i3.1321

Sumantika, A., & Sirait, G. (2022). Productivity Measurement Using the Objective Matrix ( OMAX ) on the PT XYZ Non Woven Production Floor Pengukuran Produktivitas Menggunakan Objective Matrix ( OMAX ) di Lantai Produksi Non Woven PT XYZ. Formosa Journal of Applied Sciences, 1(6), 1157–1168. https://doi.org/10.55927/fjas.v1i6.1866

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Ade Dwi sakti, Misra Hartati , Muhammad Nur , Harpito Harpito

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

.png)