Quality Improvement of Health Plaster Products With Six Sigma Method and QCDSME Analysis

DOI:

https://doi.org/10.12928/si.v22i1.176Keywords:

Quality Improvement, Six Sigma, QCDSME, Fishbone DiagramAbstract

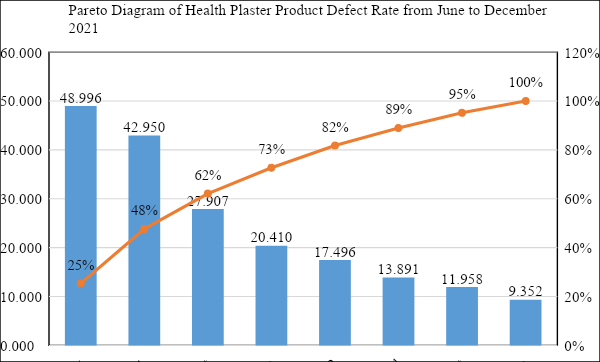

Health plasters are one of a pharmaceutical company's excellent items. There are still defective products in the manufacturing process, including torn paper, joint 1, not cut, perforated edges, joint 2, tucked, long-short, and asymmetrical. Research conducted between June and December 2021 reveals that 192.960 Kg of substandard items were discovered. The contribution of this research is to identify the underlying reasons of the problem and decrease the number of product faults. By using the QCDSME (Quality-Cost-Delivery-Safety-Morale) method analysis in the cost stage, this company is known to experience losses due to defective products of IDR 18,047,232 / year. The results of the analysis using the six sigma method at the analyze stage using the fishbone diagram tool are known that defective products are caused by the absence of size standards in the repair of plate and pressure roll positions, differences in operator responses, the absence of written procedures for handling product defects, and the existence of product roll rolls that are too loose or tight. The improvement proposal made next is to make a size standard for the plate position with a value of 12.5 ± 1 cm and a pressure roll with a value of 22 ± 1 mm with additional tools in the form of a ruler. After taking corrective steps and quality control on product defects, the results showed that the value of product defects decreased from the previous average of 1,119 pcs/day to 205 pcs/day, so that the company's loss value was reduced to IDR 3,306,240/year.

References

Abdussalam, M., & Adi, P. (2023). Perbaikan Zoning dan Flow Treatment Gallon Kotor dengan Metode 5R dan SQCDME. Industrial Engineering Online, 12(3), https://ejournal3.undip.ac.id/index.php/ieoj/article/view/40333.

Ariella, I. R. (2018). Pengaruh Kualitas Produk, Harga Produk Dan Desain Produk Terhadap Keputusan Pembelian Konsumen Mazelnid. Jurnal Performa: Jurnal Manajemen dan Start-up Bisnis, 3(2), 215-221, https://doi.org/10.37715/jp.v3i2.683.

Didiharyono, D., Marsal, M., & Bakhtiar, B. (2018). Analisis pengendalian kualitas produksi dengan metode six-sigma pada industri air minum PT Asera Tirta Posidonia, Kota Palopo. Sainsmat: Jurnal Ilmiah Ilmu Pengetahuan Alam, 7(2), 163-176, https://garuda.kemdikbud.go.id/documents/detail/3021304.

Escobar, C. A., Macias, D., McGovern, M., Hernandez-de-Menendez, M., & Morales-Menendez, R. (2022). Quality 4.0–an evolution of Six Sigma DMAIC. International journal of lean six sigma, 13(6), 1200-1238, https://doi.org/10.1108/IJLSS-05-2021-0091.

Gaspersz, V. (2002). Pedoman Implementasi Program Six Sigma Terintegrasi dengan ISO 9001:2000, MBNQA, dan HACCP (Pertama). PT. Gramedia Pustaka Utama.

Gaspersz, V. (2006). Continuous Cost Reduction Through Lean-Sigma Approach (Pertama). PT Gramedia Pustaka Utama, https://books.google.co.id/books?id=1S287n-_eScC&newbks.

Haryanto, E., & Novialis, I. (2019). Analisis Pengendalian Kualitas Produk Bos Rotor pada Proses Mesin CNC Lathe dengan Metode Seven Tools. Universitas Muhammadiyah Tangerang, 8(1), 69–77, http://dx.doi.org/10.31000/jt.v8i1.1595.

Parwati, C. I., Susetyo, J., & Alamsyah, A. (2019). Analisis Pengendalian Kualitas Sebagai Upaya Pengurangan Produk Cacat Dengan Pendekatan Six Sigma, Poka-Yoke Dan Kaizen. Jurnal Gaung Informatika, 12(2), https://doi.org/10.47942/gi.v12i2.376.

Rahman, A., Shaju, S. U. C., Sarkar, S. K., Hashem, M. Z., Hasan, S. M. K., & Islam, U. (2018). Application of Six Sigma using Define Measure Analyze Improve Control (DMAIC) methodology in Garment Sector. Independent Journal of Management & Production, 9(3), 810–826, https://doi.org/10.14807/ijmp.v9i3.732.

Rimantho, D., & Athiyah, A. (2019). Analisis Kapabilitas Proses Untuk Pengendalian Kualitas Air Limbah Di Industri Farmasi. Jurnal Teknologi, 11(1), 1-8, https://doi.org/10.24853/jurtek.11.1.1-8.

Rokhmah, A., Putra, H., & Gunawan, F. E. (2023). Penerapan quality control circle untuk meningkatkan yield produksi dengan mengurangi scrap di recoiling line. TEKNOSAINS: Jurnal Sains, Teknologi dan Informatika, 10(2), 244-253, https://doi.org/10.37373/tekno.v10i2.536.

Smetkowska, M., & Mrugalska, B. (2018). Using Six Sigma DMAIC to improve the quality of the production process: a case study. Procedia-Social and Behavioral Sciences, 238, 590-596, https://doi.org/10.1016/j.sbspro.2018.04.039.

Stani, A. H., Ariani, C. D., Supriyadi, D., & Gazian, M. I. (2023). Implementation of the QCDMSE Strategy in the Community Empowerment Program to Utilize the Sulawesi Masked Owls as a Natural Predator for Rodents. Prospect: Jurnal Pemberdayaan Masyarakat, 2(2), 94-103, https://garuda.kemdikbud.go.id/documents/detail/3732712.

Sugiarto, S., & Octaviana, V. (2021). Service Quality (SERVQUAL) Dimensions on Customer Satisfaction: Empirical Evidence from Bank Study. Golden Ratio of Marketing and Applied Psychology of Business, 1(2), 93-106, https://doi.org/10.52970/grmapb.v1i2.103.

Sutiyarno, D., & Chriswahyudi, C. (2019). Analisis Pengendalian Kualitas dan Pengembangan Produk Wafer Osuka dengan Metode Six Sigma Konsep DMAIC dan Metode Quality Function Deployment di PT. Indosari Mandiri. JIEMS (Journal of Industrial Engineering and Management Systems), 12(1), http://dx.doi.org/10.30813/jiems.v12i1.1535.

Tannady, Hendy. "Pengendalian kualitas." Yogyakarta: Graha Ilmu (2015).

Wirawati, S. M. (2019). “Analisis pengendalian kualitas kemasan botol plastik dengan metode Statistical Process Control (SPC) di PT. Sinar Sosro KPB Pandeglang”. Jurnal Intent: Jurnal Industri dan Teknologi Terpadu, 2(1), 94-102, https://doi.org/10.47080/intent.v2i1.524.

Yohanes, A., & Ekoanindiyo, F. A. (2021). Analisis perbaikan untuk mengurangi defect pada produk pelindung tangan dengan pendekatan lean six sigma. J. Sains dan Teknol. J. Keilmuan dan Apl. Teknol. Ind, 21(2), 127-140, https://ojs.sttind.ac.id/sttind_ojs/index.php/Sain

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Ragillia Fitri Nur Janah

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

.png)