Fuzzy-FMECA: Right Solution for Jet Dyeing Machine Damage Prevention

DOI:

https://doi.org/10.12928/si.v22i2.204Keywords:

Fuzzy-FMECA, Jet dyeing, Fabric quality, Main pump, SocketAbstract

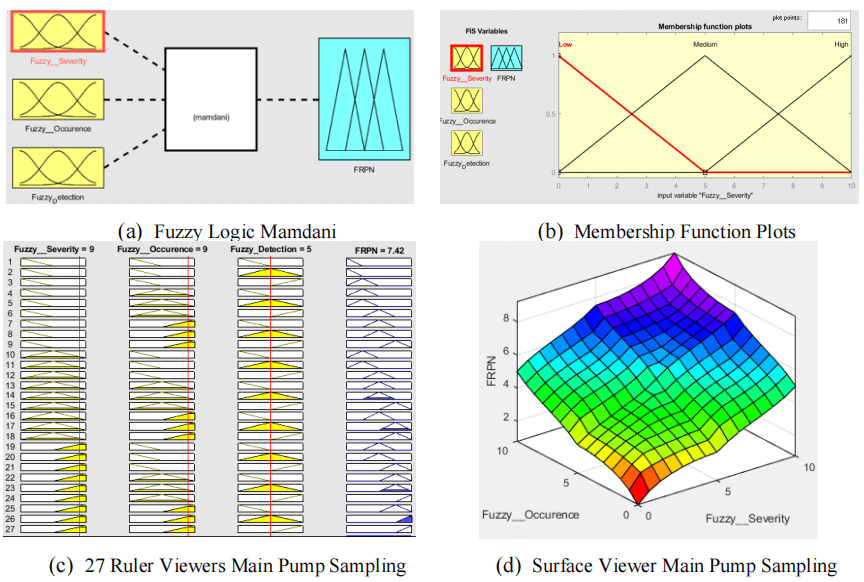

Jet dyeing machines, essential for producing high-quality and environmentally friendly textiles, face persistent issues with defects that lead to production stoppages, compromised cloth quality, and significant financial losses for companies. These challenges hinder operational efficiency and undermine the competitive edge of textile manufacturers in a rapidly evolving market. Jet Dyeing machines continue to innovate to produce high quality and environmentally friendly textiles, with the discovery of defects causing cloth production to stop, cloth quality to decline, and company losses. The Fuzzy-FMECA approach enhances accuracy and adaptability in identifying failure risks, improving maintenance for complex jet dyeing systems. This study aims to identify the root causes of jet dyeing machine damage for preventive maintenance design. Studies using robust fuzzy-FMECA can identify critical components of jet dyeing machines with a high degree of accuracy. This can improve machine reliability and reduce fabric quality failures. The dominant machine failures identified in jet dyeing components are leakage, short circuits, and installation errors. The Pareto analysis shows that leaks, tears, and short circuits are responsible for over 70% of total

failures. The most critical components include the main pump and electric socket, both with an RPN score of 7.42, representing a significant 30% of overall risk. Other high-risk components such as the steam pipe packing and heat exchanger steam pipe also have an RPN of 7.25. These findings indicate that over 60% of the failures arise from just a few key components. These findings have succeeded in identifying the critical components of the jet dyeing machine (main pump and socket) which have the highest potential risk of failure. The proposed preventive maintenance design can reduce these risks, but needs to be refined with consistent, competent and monitored inspections. The preventive maintenance design significantly mitigates risks, requiring ongoing refinement through regular, skilled, and supervised inspections to ensure optimal effectiveness.

References

Akter, N., Akter, N., Pervin, M., & Repon, M. R. (2023). The influence of mixed thickeners on printing over lyocell knitted fabric. Heliyon, 9(3), e14175, https://doi.org/10.1016/j.heliyon.2023.e14175.

Alsharief, H. H., Al-Hazmi, G. A. A., Alzahrani, S. O., Almahri, A., Alamrani, N. A., Alatawi, N. M., & El-Metwaly, N. M. (2022). Immobilization of strontium aluminate nanoparticles onto plasma-pretreated nonwoven polypropylene fibers by screen-printing toward photochromic textiles. Journal of Materials Research and Technology, 20, 3146–3157, https://doi.org/10.1016/j.jmrt.2022.08.104.

Balaraju, J., Govinda Raj, M., & Murthy, C. S. (2019). Fuzzy-FMEA risk evaluation approach for LHD machine-A case study. Journal of Sustainable Mining, 18(4), 257–268, https://doi.org/10.1016/j.jsm.2019.08.002.

Banna, B. U., Mia, R., Hasan, M. M., Ahmed, B., & Hasan Shibly, M. A. (2023). Ultrasonic-assisted

sustainable extraction and dyeing of organic cotton fabric using natural dyes from Dillenia indica leaf. Heliyon, 9(8), e18702, https://doi.org/10.1016/j.heliyon.2023.e18702.

Baradaran, A. A., & Tavazoei, M. S. (2022). Fuzzy system design for automatic irrigation of agricultural fields. Expert Systems with Applications, 210, 118602, https://doi.org/https://doi.org/10.1016/j.eswa.2022.118602.

Behera, M. K., Majumder, I., & Nayak, N. (2018). Solar photovoltaic power forecasting using optimized modified extreme learning machine technique. Engineering Science and Technology, an International Journal, 21(3), 428–438. https://doi.org/10.1016/j.jestch.2018.04.013

Bhattacharyya, B., & Doloi, B. (2019). Modern Machining Technology: Advanced, Hybrid, Micro Machining and Super Finishing Technology. Elsevier Science, https://books.google.co.id/books?id=eEOwDwAAQBAJ.

Bourdeau-Laferriere, C., Gaudreault, J., & Duchesne, C. (2021). Predictive models to improve the quality of a textile dyeing process. IFAC-PapersOnLine, 54(1), 385–389, https://doi.org/10.1016/j.ifacol.2021.08.043.

Buja, A., De Luca, G., Ottolitri, K., Marchi, E., De Siena, F. P., Leone, G., Maculan, P., Bolzonella, U., Caberlotto, R., Cappella, G., Grotto, G., Lattavo, G., Sforzi, B., Venturato, G., Saieva, A. M., & Baldo, V. (2023). Using Failure Mode, Effect and Criticality Analysis to improve safety in the cancer treatment prescription and administration process. Journal of Pharmaceutical Policy and Practice, 16(1), 1–8, https://doi.org/10.1186/s40545-023-00512-9.

Catic, N., Wells, L., Al Nahas, K., Smith, M., Jing, Q., Keyser, U. F., Cama, J., & Kar-Narayan, S. (2020). Aerosol-jet printing facilitates the rapid prototyping of microfluidic devices with versatile geometries and precise channel functionalization. Applied Materials Today, 19, https://doi.org/10.1016/j.apmt.2020.100618.

Chakraborty, J. N., & Chakraborty, J. N. (2015). Fundamentals and Practices in Colouration of Textiles. WPI India. https://books.google.co.id/books?id=qUf7CAAAQBAJ

Cie, C. (2015). Ink Jet Textile Printing. Elsevier Science, https://books.google.co.id/books?id=KruYBAAAQBAJ.

Crespo del Castillo, A., Marcos, J. A., & Parlikad, A. K. (2023). Dynamic fleet maintenance management model applied to rolling stock. Reliability Engineering and System Safety, 240(January), https://doi.org/10.1016/j.ress.2023.109607.

Di Nardo, M., Murino, T., Osteria, G., & Santillo, L. C. (2022). A New Hybrid Dynamic FMECA with Decision-Making Methodology: A Case Study in An Agri-Food Company. Applied System Innovation, 5(3), https://doi.org/10.3390/asi5030045.

Elbadawi, I. A., Arafat Ashmawy, M., Ahmad Yusmawiza, W., Ali Chaudhry, I., Ben Ali, N., & Ahmad, A. (2018). Application of Failure Mode Effect and Criticality Analysis (FMECA) to a Computer Integrated Manufacturing (CIM) Conveyor Belt. Technology & Applied Science Research, 8(3), 3023–3027, https://doi.org/10.48084/etasr.2043.

Errouha, M., Derouich, A., Motahhir, S., Zamzoum, O., El Ouanjli, N., & El Ghzizal, A. (2019). Optimization and control of water pumping PV systems using fuzzy logic controller. Energy Reports, 5, 853–865, https://doi.org/10.1016/j.egyr.2019.07.001.

Fumagalli, L., Elefante, D., Macchi, M., & Iung, B. (2008). Evaluating the Role of Maintenance Maturity in Adoption of New ICT in the Process Industry. In IFAC Proceedings Volumes (Vol. 41, Issue 3). IFAC, https://doi.org/10.3182/20081205-2-cl-4009.00045.

Grooss, O. F. (2022). Advancing maintenance strategies through digitalization: A case study. Procedia Computer Science, 217(2022), 1522–1531, https://doi.org/10.1016/j.procs.2022.12.352.

Hannan, M. A., Islam, M. F., & Hoque, M. B. (2023). Improvement of mahogany leaf extract dye fixation on cotton-modal blend. Heliyon, 9(10), e20786, https://doi.org/10.1016/j.heliyon.2023.e20786.

He, Y., Luckett, J., Begines, B., Dubern, J. F., Hook, A. L., Prina, E., Rose, F. R. A. J., Tuck, C. J., Hague, R. J. M., Irvine, D. J., Williams, P., Alexander, M. R., & Wildman, R. D. (2022). Ink-jet 3D printing as a strategy for developing bespoke non-eluting biofilm resistant medical devices. Biomaterials, 281(November 2021), https://doi.org/10.1016/j.biomaterials.2021.121350.

Horrocks, A. R., & Anand, S. C. (2015). Handbook of Technical Textiles: Technical Textile Processes. Elsevier Science. https://books.google.co.id/books?id=QUqdBAAAQBAJ

Iadanza, E., Zacchia, M., Pennati, D., Manetti, L., Bocchi, L., & Gherardelli, M. (2021). Fuzzy FMECA Process Analysis for Managing the Risks in the Lifecycle of a CBCT Scanner. IEEE Access, 9, 135723–135741, https://doi.org/10.1109/ACCESS.2021.3117703.

Ja’fari, M., Shojae, F. J., & Jaworski, A. J. (2023). Synthetic jet actuators: Overview and applications. International Journal of Thermofluids, 20 (August), 100438, https://doi.org/10.1016/j.ijft.2023.100438.

Wirth, M., Shea, K., & Chen, T. (2023). 3D-printing textiles: multi-stage mechanical characterization of additively manufactured biaxial weaves. Materials and Design, 225, 11449, https://doi.org/10.1016/j.matdes.2022.111449.

Younesi Heravi, M., Yeganeh, A., & Razavian, S. B. (2022). Using Fuzzy Approach in Determining Critical Parameters for Optimum Safety Functions in Mega Projects (Case Study: Iran’s Construction Industry) BT - Frontiers in Nature-Inspired Industrial Optimization (M. Khosravy, N. Gupta, & N. Patel (eds.); pp. 183–200). Springer Singapore, https://doi.org/10.1007/978-981-16-3128-3_10.

Zhao, X. Y., Jun, F., Wang, F., Cao, X. X., Du, Z. Q., Wang, Y., & Long, J. J. (2023). Investigation of the uptake and compatibility behaviors of special disperse dyes developed for sustainable color matching in supercritical carbon dioxide. Journal of CO2 Utilization, 72(April), 102478, https://doi.org/10.1016/j.jcou.2023.102478.

Zuniga, A. A., Fernandes, J. F. P., & Branco, P. J. C. (2023). Fuzzy-Based Failure Modes, Effects, and Criticality Analysis Applied to Cyber-Power Grids. Energies, 16(8), https://doi.org/10.3390/en16083346

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Tiaradia Ihsan

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

.png)