Barrier Factors Model of Innovation Process in the Furniture Industry Supply Chain (Case Study at PT. Duwa Atmimuda)

DOI:

https://doi.org/10.12928/si.v21i1.55Keywords:

Innovation, Furniture, Interpretive Structural Modelling (ISM), MICMACAbstract

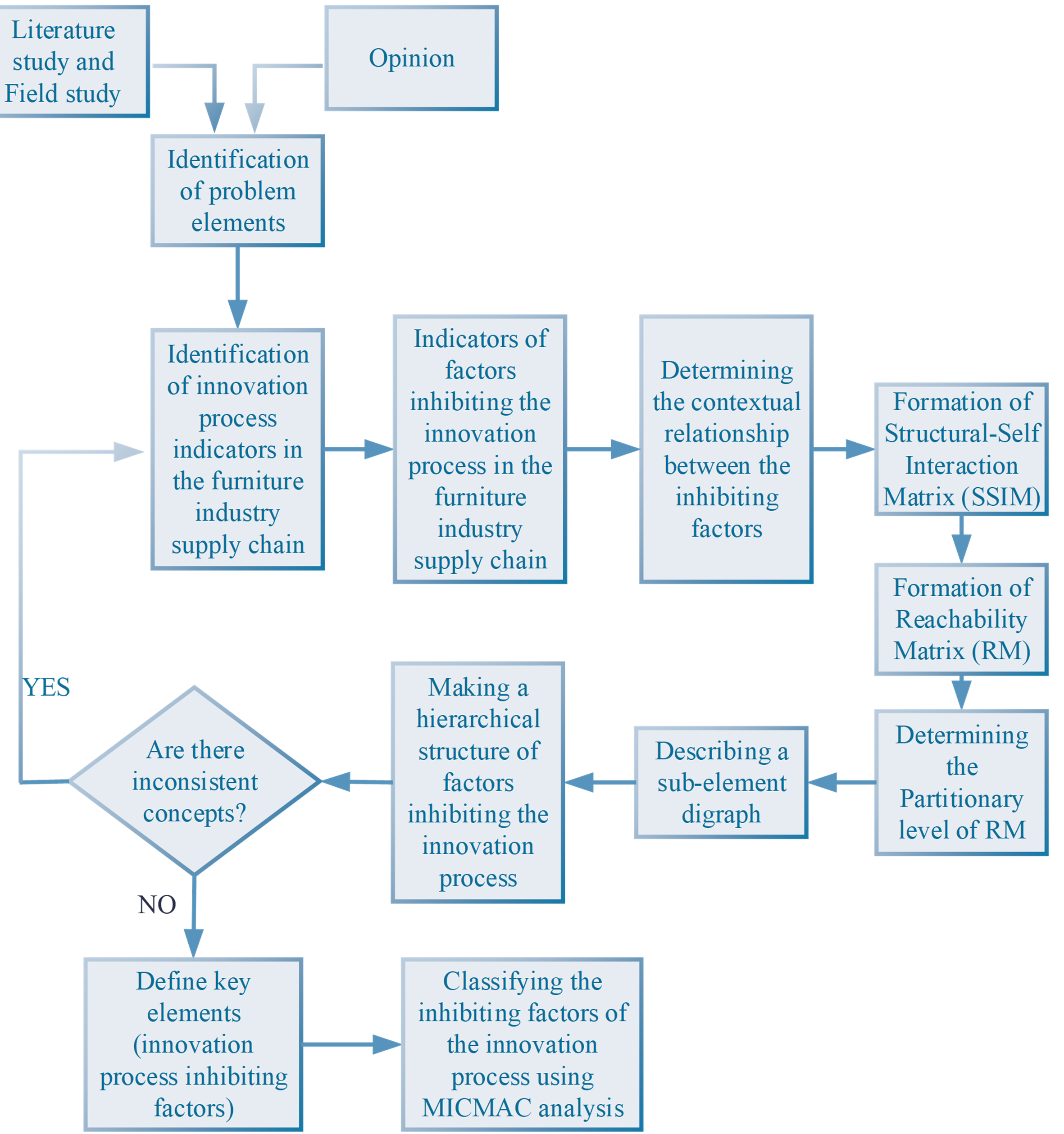

PT. Duwa Atmimuda is a company engaged in manufacturing in producing stainless metal products and furniture frames. PT. Duwa Atmimuda is experiencing problems with the lack of application of technology in terms of marketing, seen from the absence of social media utilization, causing the company to find it difficult to expand market share. This study aims to identify the factors that hinder the company's innovation process using the Interpretive Structural Modeling (ISM) method and classify the model using MICMAC Analysis. The results showed that the ISM model of the barrier factor for the innovation process in the furniture industry supply chain has 6 levels. After the ISM model is obtained, the next process is to classify each variable indicator on the barrier factors of the innovation process with the help of MICMAC analysis. There are 4 classification clusters, the first cluster (autonomous indicators) has one indicator. While in the second cluster (dependent indicators) there is one indicator. In the third cluster (linkage indicators) there are 9 indicators. In the fourth cluster (independent indicators) there is one indicator. The third cluster (linkage indicators) is the highest cluster of indicator spreads where this indicator has high control and dependence. The conclusion of this study is that there are 12 inhibiting factors in the innovation process which are arranged into six levels of the ISM model and in the MICMAC analysis the third cluster is the highest distribution cluster.

References

Awan, U., Kraslawski, A., & Huiskonen, J. (2018). Understanding influential factors on implementing social sustainability practices in Manufacturing Firms: An interpretive structural modelling (ISM) analysis. Procedia Manufacturing, 17, 1039–1048. https://doi.org/10.1016/j.promfg.2018.10.082.

Ali, S. M., Hossen, M. A., Mahtab, Z., Kabir, G., & Paul, S. K. (2020). Barriers to lean six sigma implementation in the supply chain: An ISM model. Computers & Industrial Engineering, 149, 106843. https://doi.org/10.1016/j.cie.2020.106843.

Badri, S., & Marjukah, A. (2017). Model Kinerja Competitiveness Industri Furniture Kabupaten Klaten. IENACO, 465–470.

Chen, W. K., Nalluri, V., Lin, M. L., & Lin, C. T. (2021). Identifying decisive socio-political sustainability barriers in the supply chain of banking sector in india: Causality analysis using ism and micmac. Mathematics, 9(3), 1–23. https://doi.org/10.3390/math9030240.

Debnath, B., Shakur, M. S., Bari, A. M., & Karmaker, C. L. (2023). A Bayesian Best–Worst approach for assessing the critical success factors in sustainable lean manufacturing. Decision Analytics Journal, 6, 100157. https://doi.org/10.1016/j.dajour.2022.100157.

Digalwar, A. K., Mundra, N., Tagalpallewar, A. R., & Sunnapwar, V. K. (2017). Road map for the implementation of green manufacturing practices in Indian manufacturing industries: An ISM approach. Benchmarking: An International Journal, 24(5), 1386–1399. https://doi.org/10.1108/BIJ-08-2015-0084.

Epede, M. B., & Wang, D. (2022). Competitiveness and upgrading in global value chains: A multiple-country analysis of the wooden furniture industry. Forest Policy and Economics, 140, 102737. https://doi.org/10.1016/j.forpol.2022.102737.

Fahmi, F. Z., Koster, S., & Van Dijk, J. (2016). The location of creative industries in a developing country: The case of Indonesia. Cities, 59, 66-79. https://doi.org/10.1016/j.cities.2016.06.005.

Ghalamsiah, L., Afshar-Kazemie, M., Seyedhosseini, M., & Torabi, T. (2020). Structuring Effective Factors on Maturity of Technology Using the ISM Method. Journal of System Management (JSM), 6(4), 225–241. https://doi.org/10.30495/jsm.2021.1917245.1417.

Haleem, A., Khan, S., & Khan, M. I. (2019). Traceability implementation in food supply chain: A grey-DEMATEL approach. Information Processing in Agriculture, 6(3), 335-348. https://doi.org/10.1016/j.inpa.2019.01.003.

Jia, P., Diabat, A., & Mathiyazhagan, K. (2015). Analyzing the SSCM practices in the mining and mineral industry by ISM approach. Resources Policy, 46, 76-85. https://doi.org/10.1016/j.resourpol.2014.04.004.

Khan, U., & Haleem, A. (2015). Improving to Smart Organization: An integrated ISM and fuzzy- MICMAC modelling of barriers. Journal of Manufacturing Technology Management, 26(6), 807–829. https://doi.org/10.1108/JMTM-05-2014-0062.

Kumar, M., & Rao, T. J. (2023). Use of TISM and MICMAC methods to assess the influence of behavioral factors on the employment of GSCM in the Indian leather industry. MethodsX, 102164. https://doi.org/10.2139/ssrn.4368157.

Kumar, P., Bhamu, J., & Sangwan, K. S. (2018). Analysis of Barriers to Industry 4.0 adoption in Manufacturing Organizations: an ISM Approach. Procedia CIRP, 72(ii), 940–946. https://doi.org/10.1016/j.procir.2021.01.010.

Lobaccaro, G., Croce, S., Lindkvist, C., Probst, M. C. M., Scognamiglio, A., Dahlberg, J., Lundgren, M. & Wall, M. (2019). A cross-country perspective on solar energy in urban planning: Lessons learned from international case studies. Renewable and Sustainable Energy Reviews, 108, 209-237. https://doi.org/10.1016/j.rser.2019.03.041.

Lu, C. W., & Lu, J. M. (2017). Evaluation of the Indonesian National Standard for elementary school furniture based on children's anthropometry. Applied ergonomics, 62, 168-181. https://doi.org/10.1016/j.apergo.2017.03.004.

Primadasa, R., Sokhibi, A., & Tauhida, D. (2019, August). Interrelationship of green supply chain management (GSCM) performance indicators for palm oil industry in Indonesia. In IOP Conference Series: Materials Science and Engineering (Vol. 598, No. 1, p. 012034). IOP Publishing. https://doi.org/10.1088/1757-899X/598/1/012034.

Rachmayanti, S. (2021). Ekspor Industri Furniture Tumbuh 5 Persen di Tengah Pandemi Covid-19. https://www.idxchannel.com/economics/ekspor-industri-furniture-tumbuh-5-persen-di-tengah-pandemi-covid-19.

Rashin, M. A., & Ghina, A. (2018). Identifikasi Inovasi dan kinerja bisnis dalam meningkatkan daya saing. Jurnal Penelitian Pendidikan, 18(2), 213-219. https://doi.org/10.17509/jpp.v18i2.12963.

Rofaida, R., Suryana, Asti Nur Aryanti, & Yoga Perdana. (2020). Strategi Inovasi pada Industri Kreatif Digital: Upaya Memperoleh Keunggulan Bersaing pada Era Revolusi Industri 4.0. Jurnal Manajemen Dan Keuangan, 8(3), 402–414. https://doi.org/10.33059/jmk.v8i3.1909.

Segara, G. A., Kusmantini, T., & Utami, Y. (2019). Effect of Value Chain Activities on Product Quality and Innovation. Business Innovation and Entrepreneurship Journal, 1(3), 191–202. https://doi.org/10.35899/biej.v1i3.71.

Singh, C., Singh, D., & Khamba, J. S. (2020). Developing a conceptual model to implement green lean practices in Indian manufacturing industries using ISM-MICMAC approach. Journal of Science and Technology Policy Management, 12(4), 587–608. https://doi.org/10.1108/JSTPM-08-2019-0080.

Sun, C., Xu, H., & Jiang, S. (2020). Understanding the risk factors of BIM technology implementation in the construction industry: An interpretive structural modeling (ISM) approach. Engineering, Construction and Architectural Management, 27(10), 3289-3308. https://doi.org/10.1108/ECAM-09-2019-0508.

Taghavi, E., Fallahpour, A., Wong, K. Y., & Hoseini, S. A. (2021). Identifying and prioritizing the effective factors in the implementation of green supply chain management in the construction industry. Sustainable Operations and Computers, 2, 97-106. https://doi.org/10.1016/j.susoc.2021.05.003.

Ulfa, R., Setyadi, D., & Nahar, M. (2021). Pengaruh Inovasi Proses, Inovasi Produk, dan Teknologi Terhadap Kinerja Operasional Pada PT Pagilaran UP Pagilaran Batang, Jawa Tengah. Indicators: Journal of Economic and Business, 3(1), 434–444. https://doi.org/10.47729/indicators.v3i1.83.

Vitaloka, R. (2020). The effect of innovation strategy on company operational performance (Case study of MSME in Jambi). Dspace Repository. https://dspace.uii.ac.id/handle/123456789/29175.

Yang, Z., & Lin, Y. (2020). The effects of supply chain collaboration on green innovation performance: An interpretive structural modeling analysis. Sustainable Production and Consumption, 23, 1-10. https://doi.org/10.1016/j.spc.2020.03.010.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Wiwik Pratiwi, Rangga Primadasa, Vikha Indira Asri, Wisnu Budi Waluyo

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

.png)