Assessing Cause of Defect Using Failure Mode and Effect Analysis

DOI:

https://doi.org/10.12928/si.v21i1.91Keywords:

Defect, FMEA, Ishikawa Diagram, QualityAbstract

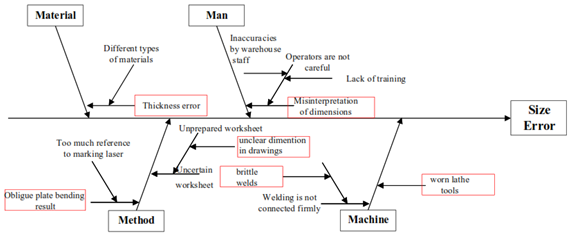

A company should implement good quality management to maintain consumer confidence in producing quality products. FMEA serves to identify product failures in a process and the causes of defects or losses that occur during the production process of a product, component, or system. The research aims to analyze quality control and identify production defects that cause a decrease in quality. The samples studied were rejected goods in production activities. Forty damaged parts were used as the samples in this study. This study used both qualitative and quantitative analysis. Quantitative analysis was conducted to determine the type of rejection and then to rank the risk, while qualitative analysis was performed with Ishikawa diagram to evaluate risk priorities. This research not only helps identify and assess the root cause of rejected goods but also affects the following year's planning by proposing measures to reduce risk. Check sheets and histograms are used to present further research. The analysis results show two classifications of defects in production: size error and painting error, with the most dominant defect, size error, and equal to 73.17%. Based on the analysis of the causes of defects, several factors were found that caused product defects; man, material, method, machine. The man factor has the highest value in contributing to defect, with an RPN score of 192.

References

Agrawal, M. (2021). Impact of Ishikawa on the analysis of data in mechanical industries. Materials Today: Proceedings, 81, 1040-1045. https://doi.org/10.1016/j.matpr.2021.04.376.

Besterfield, D. H. (2009). Quality Control. 8th edition. New Jersey: Pearson Prentice Hall. https://www.worldcat.org/title/quality-control/oclc/193908300.

Carvalho, R., Lobo, M., Oliveira, M., Oliveira, A. R., Lopes, F., Souza, J., Ramalho, A., Viana, J., Alonso, V., Caballero, I., Santos, J. V., & Freitas, A. (2021). Analysis of root causes of problems affecting the quality of hospital administrative data: A systematic review and Ishikawa diagram. International Journal of Medical Informatics, 156. https://doi.org/10.1016/j.ijmedinf.2021.104584.

Dai, W., Maropoulos, P. G., Cheung, W. M., & Tang, X. (2011). Decision-making in product quality based on failure knowledge. International Journal of Product Lifecycle Management, 5(2–4), 143–163. https://doi.org/10.1504/IJPLM.2011.043185.

Grosfeld-Nir, A., Ronen, B., & Kozlovsky, N. (2007). The Pareto managerial principle: when does it apply?. International Journal of Production Research, 45(10), 2317-2325. https://doi.org/10.1080/00207540600818203.

Judi, H. M., Genasan, D., & Jenal, R. (2011). Quality control implementation in manufacturing companies: motivating factors and challenges. INTECH Open Access Publisher. https://doi.org/10.5772/15997.

Kardos, P., Lahuta, P., & Hudakova, M. (2021). Risk Assessment Using the FMEA method in the Organization of Running Events. Transportation Research Procedia, 55, 1538–1546. https://doi.org/10.1016/j.trpro.2021.07.143.

Kim, J., & Lim, C. (2021). Customer complaints monitoring with customer review data analytics: An integrated method of sentiment and statistical process control analyses. Advanced Engineering Informatics, 49, 101304. https://doi.org/10.1016/j.aei.2021.101304.

Liu, H. C., Chen, X. Q., Duan, C. Y., & Wang, Y. M. (2019). Failure mode and effect analysis using multi-criteria decision making methods: A systematic literature review. Computers and Industrial Engineering, 135, 881–897. https://doi.org/10.1016/j.cie.2019.06.055.

Liu, J., Wang, D., Lin, Q., & Deng, M. (2023). Risk assessment based on FMEA combining DEA and cloud model: A case application in robot-assisted rehabilitation. Expert Systems with Applications, 214, 119119. https://doi.org/10.1016/j.eswa.2022.119119.

Mikulak, R. J., McDermott, R., & Beauregard, M., (2013). The Basics of FMEA. https://doi.org/10.1201/b16656.

Mizuno, S. (2020). Management for quality improvement: the 7 new QC tools. CRC Press. https://doi.org/10.1201/9781003070450-3.

Nguyen, Q. V., Miller, N., Arness, D., Huang, W., Huang, M. L., & Simoff, S. (2020). Evaluation on interactive visualization data with scatterplots. Visual Informatics, 4(4), 1–10. https://doi.org/10.1016/j.visinf.2020.09.004.

Perera, H. E., & Navaratne, S., (2016). Application of Pareto principle and Fishbone diagram for Waste Management in a Powder Filling Process. International Journal of Scientific & Engineering Research, 7(11), 181–184. https://www.ijser.org/onlineResearchPaperViewer.

Shebl, N. A., Franklin, B. D., & Barber, N. (2012). Failure mode and effects analysis outputs: Are they valid? BMC Health Services Research, 12(1). https://doi.org/10.1186/1472-6963-12-150.

Sui, Y., Ding, R., & Wang, H. (2020). A novel approach for occupational health and safety and environment risk assessment for nuclear power plant construction project. Journal of Cleaner Production, 258, 120945. https://doi.org/10.1016/j.jclepro.2020.120945.

Wang, H. (2009). Comparison of p control charts for low defective rate. Computational Statistics and Data Analysis, 53(12), 4210–4220. https://doi.org/10.1016/j.csda.2009.05.024.

Wang, L., Yan, F., Wang, F., & Li, Z. (2021). FMEA-CM based quantitative risk assessment for process industries—A case study of coal-to-methanol plant in China. Process Safety and Environmental Protection, 149, 299–311. https://doi.org/10.1016/j.psep.2020.10.052.

Wawolumaja, R., and Muis, R., (2013). Diktat Kuliah Pengendalian & Penjaminan Kualitas (Ie-501) Failure Mode Effect Analysis (FMEA). Universitas Kristen Maranatha. Bandung. https://adoc.pub/diktat-kuliah-pengendalian-penjaminan-kualitas-ie-501151714984153426.html.

Wong, K.C. (2011). Using an Ishikawa Diagram as A Tool to Assist Memory and Retrieval of Relevant Medical Cases from the Medical Literature. Journal of Medical Reports. 5(120). https://doi.org/10.1186/1752-1947-5-120.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Berty Dwi Rahmawati, Nadia Nisya Budi Maharani

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

.png)