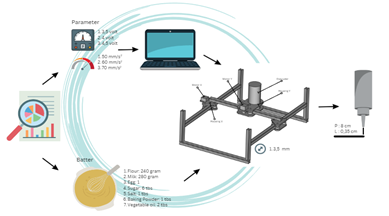

Parameter Optimization of Printcake Machine Using Full Factorial

DOI:

https://doi.org/10.12928/si.v21i1.97Keywords:

Full factorial, Printcake, Micropump voltage, Velocity, Food 3D printingAbstract

This research analyzes pancake batter and discovers the ideal printing parameters on the HALTech Printcake machine, the machine was newly developed and hasn’t been optimize yet where the prior research on 3D Printing pancake batter never been done. This research aim to optimize the printing parameter in order to get pancake close to proposed design. 3 Level full factorial were carried out to understand the response of all the available combination of parameter. There are 2 parameters proposed on this research velocity: 50 mm/s, 60 mm/s, 70 mm/s, and micropump voltage: 3.5 volts, 4 volts, and 4.5 volts. Balance between two parameter needed in order to get the best printing result, Velocity refer to the movement speed of the axis and the micropump voltage refer to how many material will be extrude or flow rate. Design specimen of a straight line 8 cm long and 0.35 cm wide proposed. The results showed that the length error was not significantly affected either by the velocity of the axis movement or the micropump voltage, whereas for the printed area error, it was significantly affected by the velocity, and for the micropump voltage, it did not have a significant effect. Optimized combination of parameter obtain in this research was velocity of 70 mm/s, and a micropump voltage of 4 volts and overall was able to print better specimen then the average experiment in term of printed area error.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Ahmad Amirudin Assidiq, Hasan Mastrisiswadi, Herianto

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

.png)