Risk and Reliability Improvement Analysis of Boiler System Using the Failure Mode Effect Analysis & Critical Analysis (FMECA) Method

DOI:

https://doi.org/10.12928/si.v21i1.98Keywords:

Risk Analysis, Reliability, FMECA, Boiler SystemAbstract

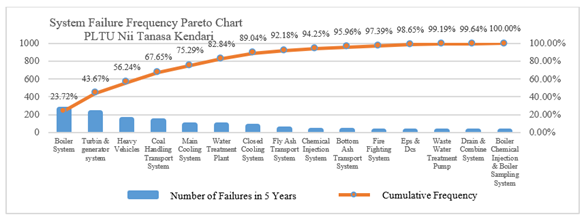

Electrical energy is a vital source of energy for human life. Currently, various power plants can provide electrical energy, one of which is the Steam Power Plant (PLTU). A PLTU must carry out operational tasks repeatedly and continuously to meet electricity needs. Based on historical data for PT. PJB Service Kendari for the last three years, there has been an increasing trend of downtime and derating at PLTU Nii Tanasa Kendari in the 2019–2021 timeframe. The boiler system is one of the systems that often experiences disturbances. FMECA is required to carry out a risk analysis to find out in detail the causes, effects, impacts, and ways of mitigating risks, as well as sorting and labeling risks for critical components based on the RPN value. The boiler itself is the main component and is supported by other components in the steam-water process. The reliability value is determined after the critical component with a high level of risk is marked “Not Accepted”. The findings of the risk and reliability analysis will be used to mitigate risks and increase the value of the reliability of critical components. The results of reliability calculations based on MTTF found that 9 out of 13 critical components had a reliability value below 50%; increasing reliability values could be achieved using preventive maintenance (Rm(t)), and maintaining reliability values above 60% could be achieved using periodic component replacement (R(t-nT)) based on the MTTR data of each critical component.

References

ARMY. (2006). Failure Modes, Effects and Criticality Analysis (FMECA) For Command, Control, Communications, Computer, Intelligence, Surveillance, And Reconnaissance (C4ISR) Facilities. Headquarters Department of the Army. https://www.wbdg.org/ffc/army-coe/technical-manuals-tm/tm-5-698-4.

Brahim, I. B., Addouche, S. A., El Mhamedi, A., & Boujelbene, Y. (2019). Build a Bayesian network from FMECA in the production of automotive parts: diagnosis and prediction. IFAC-PapersOnLine, 52(13), 2572-2577, https://doi.org/10.1016/j.ifacol.2019.11.594.

Cristea, G., & Constantinescu, D. M. (2017, October). A comparative critical study between FMEA and FTA risk analysis methods. In IOP Conference Series: Materials Science and Engineering. 252. 1. 012046. IOP Publishing. https://doi.org/10.1088/1757-899X/252/1/012046.

Ebeling, C. E. (2019). An introduction to reliability and maintainability engineering. Waveland Press. https://books.google.co.id/books?hl=en&lr=&id=rh2WDwAAQBAJ&oi.

Hisprastin, Y., & Musfiroh, I. (2021). Ishikawa diagram dan failure mode effect analysis (FMEA) sebagai metode yang sering digunakan dalam manajemen risiko mutu di industri. Majalah Farmasetika, 6(1), 1-9. https://doi.org/10.24198/mfarmasetika.v6i1.27106.

Ismail, Z., Alkaff, A., & Gamayanti, N. (2014). Analisis Keandalan pada Heat Recovery Steam Generator (HRSG) di PT. PJB UP Gresik menggunakan metode Failure Mode Effect and Criticality Analysis (FMECA). JURNAL TEKNIK POMITS, 1(1), 1-6. https://doi.org/10.38038/vocatech.v2i2.53.

Melani, A. H. A., Murad, C. A., Netto, A. C., de Souza, G. F. M., & Nabeta, S. I. (2018). Criticality-based maintenance of a coal-fired power plant. Energy, 147, 767-781. https://doi.org/10.1016/j.energy.2018.01.048.

Mohanty, J. K., Dash, P. R., & Pradhan, P. K. (2020). FMECA analysis and condition monitoring of critical equipments in super thermal power plant. International Journal of System Assurance Engineering and Management, 11(3), 583-599. https://doi.org/10.1007/s13198-020-00945-4.

Pamungkas, I., & Dirhamsyah, M. (2019, May). Monte Carlo simulation for predicting the reliability of a boiler in the Nagan Raya steam power plant. In IOP Conference Series: Materials Science and Engineering. 523. 1. 012071). IOP Publishing. https://doi.org/10.1088/1757-899X/523/1/012071.

Pamungkas, I., Irawan, H. T., & Pandria, T. A. (2021). Implementasi Preventive Maintenance untuk Meningkatkan Keandalan pada Komponen Kritis Boiler di Pembangkit Listrik Tenaga Uap. VOCATECH: Vocational Education and Technology Journal, 2(2), 73-79.. https://doi.org/10.1088/1757-899X/523/1/012071.

Patil, S. S., & Bewoor, A. K. (2021). Reliability analysis of a steam boiler system by expert judgment method and best-fit failure model method: a new approach. International Journal of Quality & Reliability Management, 38(1), 389-409. https://doi.org/10.1108/IJQRM-01-2020-0023.

Pratiwi, P., & Hadi, Z. (2022). Production Process of Steam Power Plant and Calculation of Thermal Efficiency: Case Study of Teluk Sirih Steam Power Plant. Jurnal Teknik Mesin, 12(1), 26-31. https://jtm.itp.ac.id/index.php/jtm/article/view/693.

Puthillath, B., & Sasikumar, R. (2012). Selection of maintenance strategy using failure mode effect and criticality analysis. International Journal of Engineering and Innovative Technology (IJEIT), 1(6), 73-79. https://www.ijeit.com/vol%201/Issue%206/IJEIT1412201206_14.pdf.

Putra, G. P., & Hardi Purba, H. (2018). Failure mode and effect analysis power plant boiler. Journal of Optimization in Industrial Engineering, 11(2), 1-5. https://doi.org/10.22094/joie.2018.555547.1527.

Putri, E. L., Bahauddin, A., & Ferdinant, P. F. (2013). Usulan Jadwal Perawatan pada Mesin Electric Arc Furnace 5 dengan Simulasi Monte Carlo. Jurnal Teknik Industri Untirta, 1(4). https://onesearch.id/Record/IOS3829.article-335.

Rahman, A., & Fahma, F. (2021). Penggunaan Metode Fmeca (Failure Modes Effects Criticality Analysis) Dalam Identifikasi Titik Kritis Di Industri Kemasan. Jurnal Teknologi Industri Pertanian, 31(1), 110-119. https://doi.org/10.24961/j.tek.ind.pert.2021.31.1.110.

Rahmania, W. S., Prasetya, H. E. G., & Sholihah, F. H. (2020, September). Maintenance analysis of boiler feed pump turbine using failure mode effect analysis (FMEA) methods. In 2020 International Electronics Symposium (IES) (pp. 54-59). IEEE. https://doi.org/10.1109/IES50839.2020.9231886.

Singh, J., Singh, S., & Singh, A. (2019). Distribution transformer failure modes, effects and criticality analysis (FMECA). Engineering Failure Analysis, 99, 180-191. https://doi.org/10.1016/j.engfailanal.2019.02.014.

Suharjo, B. A. M. B. A. N. G., Suharyo, O. S., & Bandono, A. (2019). Failure mode effect and criticality analysis (FMECA) for determination time interval replacement of critical components in warships radar. Journal of Theoretical and Applied Information Technology, 97(10), 2861-2870. http://repository.sttal.ac.id/420/.

Sui, Y., Ding, R., & Wang, H. (2020). A novel approach for occupational health and safety and environment risk assessment for nuclear power plant construction project. Journal of Cleaner Production, 258, 120945. https://doi.org/10.1016/j.jclepro.2020.120945.

Tanjung, W. N., Atikah, S. A., Hidayat, S., Ripmiatin, E., Asti, S. S., & Khodijah, R. S. (2019, May). Risk Management Analysis Using FMECA and ANP Methods in the Supply Chain of Wooden Toy Industry. In IOP Conference Series: Materials Science and Engineering. 528(1), 012007. IOP Publishing. https://doi.org/10.1088/1757-899X/528/1/012007.

Ramadhan, W. D., & Nurhidayat, A. E. (2022). Analisis Perawatan Mesin dengan Menggunakan Metode Reability Centered Maintenance dan Fuzzy Fuzzy Failure Mode and Effect Analysis. Jurnal Indonesia Sosial Teknologi, 3(08), 867-878. https://doi.org/10.36418/jist.v3i8.474.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Muhammad Hudzaly Hatala, Bambang Purwanggono Sukarsono, Denny Nukertamanda

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

.png)