Economic Production Quantity Model under Back Order, Rework, Imperfect Quality, Electricity Tariff, and Emission Tax

DOI:

https://doi.org/10.12928/si.v23i1.233Keywords:

Economic production quantity, Electricity tariff, Emission tax , SustainabilityAbstract

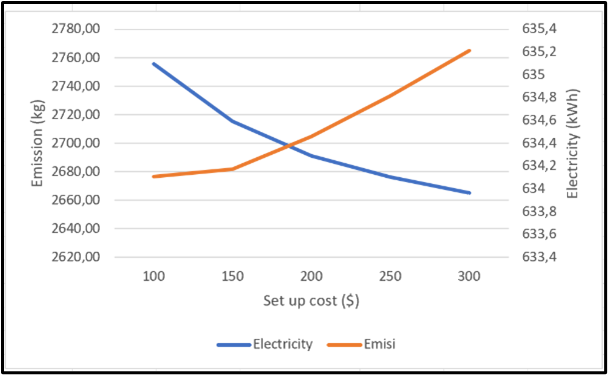

This study aims to develop a novel Economic Production Quantity (EPQ) model that integrates important sustainability and operational factors reorders, rework, imperfect quality, emission taxes, and variable electricity tariffs- by minimizing the total inventory cost while considering environmental and energy-related constraints. The model is formulated as an Integer Non-Linear Programming (INLP) problem, with two main decision variables: the total number of products produced in a cycle (y) and the maximum allowable reorder level (w). To solve this complex optimization problem, the Genetic Algorithm (GA) is used for its efficiency in handling non-linear and combinatorial problems. In addition, a sensitivity analysis is performed to assess the impact of various parameters on the total cost. Numerical experiments show that increasing emission taxes, electricity tariffs, and installation costs significantly increase the total inventory and production costs. In particular, higher emission taxes and electricity tariffs amplify the financial burden on manufacturers, underscoring the economic implications of environmental regulations and energy use. These findings emphasize integrating operational and ecological considerations into production planning. This study contributes to the field by offering a comprehensive framework that supports sustainable manufacturing practices through cost-effective inventory management. The proposed EPQ model enables manufacturers to balance economic performance and ecological responsibility, aligning operational strategies with sustainability goals and regulatory compliance.

References

Afriyanti, Y., Sasana, H., Jalunggono, G., Ekonomi, F., & Tidar, U. (2020). Analisis Faktor-Faktor Yang Mempengaruhi Konsumsi Energi Terbarukan Di Indonesia Analysis. DINAMIC: Directory Journal of Economic Volume 2 Nomor 3, 2(3). https://doi.org/10.31002/dinamic.v2i3.1428

Ahmad, W., Darma, I., Sofiana, A., & Marsetiya, D. (2024). Sustainability Analytics and Modeling An integrated inventory model for a supply chain system with two competing retailers , carbon emissions , and price-and-service dependent demand. Sustainability Analytics and Modeling, 4(August 2023), 100029. https://doi.org/10.1016/j.samod.2024.100029

Alamri, O. A., Jayaswal, M. K., Khan, F. A., & Mittal, M. (2022). An EOQ Model with Carbon Emissions and Inflation for Deteriorating Imperfect Quality Items under Learning Effect. Sustainability (Switzerland), 14(3), 1–18. https://doi.org/10.3390/su14031365

Aldhaheri, M. (2020). Sustainable Inventory Management Model for High-Volume Material with Limited Storage Space under Stochastic Demand and Supply. University of Exeter. http://hdl.handle.net/10871/121508

Anggita, R. F., Jauhari, W. A., & Rosyidi, C. N. (2023). An Integrated Inventory Model for Distributor - Retailer Considering Transportation, Loading-Unloading, and Carbon Tax. E3S Web of Conferences, 465. https://doi.org/10.1051/e3sconf/202346502010

Chiu, S. W., Tseng, C. T., Wu, M. F., & Sung, P. C. (2014). Multi-item EPQ model with scrap, rework and multi-delivery using common cycle policy. Journal of Applied Research and Technology, 12(3), 615–622. https://doi.org/10.1016/S1665-6423(14)71641-4

Das, S. K. (2022). A Fuzzy Multi Objective Inventory Model with Production Cost and Set-up-Cost Dependent on Population. Annals of Data Science, 9(3), 627–643. https://doi.org/10.1007/s40745-022-00405-9

Dellnitz, A., Braschczok, D., Ostmeyer, J., Hilbert, M., & Kleine, A. (2020). Energy costs vs. carbon dioxide emissions in short-term production planning: A business case study. Journal of Business Economics, 90(9), 1383–1407. https://doi.org/10.1007/s11573-020-01000-1

Dixon, P. S., Elder, M. D., Rand, G. K., & Silver, E. A. (1983). A heuristic algorithm for determining lot sizes of an item subject to regular and overtime production capacities. Journal of Operations Management, 3(3), 121–130. https://doi.org/10.1016/0272-6963(83)90016-5

Dongga, J., Sarungallo, A., Koru, N., & Lante, G. (2023). Implementasi Data Mining Menggunakan Algoritma Apriori Dalam Menentukan Persediaan Barang (Studi Kasus: Toko Swapen Jaya Manokwari). G-Tech: Jurnal Teknologi Terapan, 7(1), 119–126. https://doi.org/10.33379/gtech.v7i1.1938

Evita, S. N., Muizu, W. O. Z., & Raden Tri Wayu Atmojo. (2019). Penilaian Kinerja Karyawan Dengan Menggunakan Metode Behaviorally Anchor Rating Scale dan Management By Objectives (Studi kasus pada PT Qwords Company International). Pekbis Jurnal, 9(1), 18–32. https://www.neliti.com/id/publications/164390/penilaian-kinerja-karyawan-dengan-menggunakan-metode-behaviorally-anchor-rating

Giorgi Doborjginidze, Lily Petriashvili, & Mariam Inaishvili. (2021). Optimization of Inventory Management in the Supply Chain. Journal of Communication and Computer, 16(1). https://doi.org/10.17265/1548-7709/2021.01.001

Guchhait, R., Dey, B. K., Bhuniya, S., Ganguly, B., Mandal, B., Bachar, R. K., Sarkar, B., Wee, H., & Chaudhuri, K. (2020). Investment for process quality improvement and setup cost reduction in an imperfect production process with warranty policy and shortages. RAIRO - Operations Research, 54(1), 251–266. https://doi.org/10.1051/ro/2018101

Hamdhani, M., Purwitasari, D., & Raharjo, A. B. (2022). Identifikasi Profil Konsumsi Enegri Listrik untuk Meningkatkan Pendapatan dengan Klustering. Journal of Information System,Graphics, Hospitality and Technology, 4(2), 62–70. https://doi.org/10.37823/insight.v4i2.232

Hayek, P. A., & Salameh, M. K. (2001). Production Planning & Control: The Management of Operations imperfect quality items produced Production lot sizing with the reworking of imperfect quality items produced. Production Planning & Control, 12(6), 584–590. https://doi.org/10.1080/095372801750397707

Karaoglu, A., Ozcan, C., Pekince, A., & Yasa, Y. (2023). Numbering teeth in panoramic images: A novel method based on deep learning and heuristic algorithm. In Engineering Science and Technologu, and International Journal. Elsevier. https://www.sciencedirect.com/science/article/pii/S2215098622002257

Kumar, S., Kumar, S., & Kumar, A. (2021). EPQ model under imperfect production process with customer return and partial backlogging. Malaya Journal of Matematik, 9(1), 648–654. https://doi.org/10.26637/mjm0901/0113

Mashud, A. H. M., Roy, D., Daryanto, Y., & Ali, M. H. (2020). A sustainable inventory model with imperfect products, deterioration, and controllable emissions. Mathematics, 8(11), 1–21. https://doi.org/10.3390/math8112049

Maulana, S. K. D. B., Utama, D. M., Asrofi, M. S., Ningrum, I. S., Alba, N., Ahfa, H. A., & Zein, T. A. (2019). The Capacitated Sustainable EOQ Models: Models Considering Tax Emissions. Jurnal Teknik Industri, 21(1), 12–21. https://doi.org/10.22219/jtiumm.vol21.no1.12-21

Mishra, U., Wu, J. Z., & Chiu, A. S. F. (2019). Effects of carbon-emission and setup cost reduction in a sustainable electrical energy supply chain inventory system. Energies, 12(7). https://doi.org/10.3390/en12071226

Nobil, E., Cárdenas-Barron, L. E., Loera-Hernandez, I. de J., Smith, N. R., Treviño-Garza, G., Céspedes-Mota, A., & Nobil, A. H. (2023). Sustainability Economic Production Quantity with Warm-Up Function for a Defective Production System. Sustainability (Switzerland) , 15(2). https://doi.org/10.3390/su15021397

Priyan, S., Mala, P., & Palanivel, M. (2022). A cleaner EPQ inventory model involving synchronous and asynchronous rework process with green technology investment. Cleaner Logistics and Supply Chain, 4(April), 100056. https://doi.org/10.1016/j.clscn.2022.100056

Setiawan, E. A., & Haramaini, Q. (2020). Electricity dynamic tariffs scenario on medium voltage industrial customers to reduce production cost and peak load. AIP Conference Proceedings, 2255(September). https://doi.org/10.1063/5.0014312

Shabna, A., Indah, N., Teknik, D., Teknologi, I., & Nopember, S. (2024). Strategi Pengendalian Persediaan pada Rantai Pasok Multi-Echelon untuk Fast Moving Products dengan Pendekatan Sistem Dinamik. 13(1). https://ejurnal.its.ac.id/index.php/teknik/article/view/129863/0

Siagian, D. (2018). Pengaruh Perputaran Persediaan Dan Penjualan Terhadap Laba Bersih Pada UD Flamboyan Coconut Centre Batu Bara. In Skripsi Fakultas Ekonomi dan Bisnis Islam Universitas Islam Negeri Sumatera Utara Medan. http://repository.uinsu.ac.id/5347/

Taleizadeh, A. A., Naghavi-Alhoseiny, M. S., Cardenas-Barron, L. E., & Amjadian, A. (2024). Optimization of Price, Lot Size and Backordered Level in an Epq Inventory Model With Rework Process. RAIRO - Operations Research, 58(1), 803–819. https://doi.org/10.1051/ro/2023073

Tan, M., Chen, Y., Su, Y. xin, Li, S. hu, & Li, H. (2019). Integrated optimization model for industrial self-generation and load scheduling with tradable carbon emission permits. Journal of Cleaner Production, 210, 1289–1300. https://doi.org/10.1016/j.jclepro.2018.11.005

Turkensteen, M. (2019). The trade-off between costs and carbon emissions from lot-sizing decisions. 1–24. https://doi.org/10.1080/03155986.2023.2169493

Utama, D. M., & Lubis, I. H. (2024). Economic production quantity model involving repair , waste disposal , electricity tariff , and emissions tax. 8(2), 155–169. https://doi.org/10.30656/jsmi.v8i2.8961

Utama, D. M., Santoso, I., Hendrawan, Y., & Dania, W. A. P. (2022). Integrated procurement-production inventory model in supply chain: A systematic review. Operations Research Perspectives, 9(September 2021), 100221. https://doi.org/10.1016/j.orp.2022.100221

Utama, D. M., Santoso, I., Hendrawan, Y., & Dania, W. A. P. (2023). Sustainable Production-Inventory Model with Multi-Material, Quality Degradation, and Probabilistic Demand: From Bibliometric Analysis to A Robust Model. Indonesian Journal of Science and Technology, 8(2), 171–196. https://doi.org/10.17509/ijost.v8i2.54056

Utama, D. M., Santoso, I., Hendrawan, Y., & Dania, W. A. P. (2024). A sustainable production-inventory model with CO2 emission, electricity and fuel consumption under quality degradation and stochastic demand: a case study in the agri-food industry. In Environment, Development and Sustainability (Issue 0123456789). Springer Netherlands. https://doi.org/10.1007/s10668-023-04271-0

Utama, D. M., Wardani, D. P., Halifah, S. T., & Pradikta, D. C. (2019). Model Economic Production Quantity dengan Rework Process dan Batasan Gudang. Jurnal Sistem Dan Manajemen Industri, 3(1), 43. https://doi.org/10.30656/jsmi.v3i1.1017

Xie, M., Zhan, X. X., Liu, C., & Zhang, Z. K. (2023). An efficient adaptive degree-based heuristic algorithm for influence maximization in hypergraphs. Information Processing &Management. https://www.sciencedirect.com/science/article/pii/S030645732200262X

Yang, H.-L. (2023). An optimal replenishment cycle and order quantity inventory model for deteriorating items with fluctuating demand. Supply Chain Analytics, 3(February), 100021. https://doi.org/10.1016/j.sca.2023.100021

Yee, Y. M., Sy, L., Lomibao, K., German, J. D. C., & Wee, H. M. (2023). Sustainable Economic Production Quantity Model Considering Greenhouse Gas and Wastewater Emissions. Sustainability (Switzerland), 15(4). https://doi.org/10.3390/su15043436

Zaki, D. A., & Hamdy, M. (2022). A Review of Electricity Tariffs and Enabling Solutions for Optimal Energy Management. Energies, 15(22). https://doi.org/10.3390/en15228527

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Dana Marsetiya Utama, Yolanda Dwi Asmara Putri, Shanty Kusuma Dewi

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

.png)